Lean Daily Management - Why invest in it?

Are you looking for a system to help you manage your team’s responsibilities, workload and productivity?

- How to make sure tasks gets done?

- How to quickly respond to problems?

- How to nurture a culture of improvements?

A key factor is to engage your employees. Adopting Lean Daily Management (LDM) will create a dedicated arena for involvement and engagement, resulting in improved productivity and operational excellence.

Life Without a Lean Daily Management System

You’re not getting things done even though your employees are competent and capable.

Days after explaining and delegating actions, you find that it’s not done as expected.

The problem escalates when you think of the team as a whole.

Frustration grows with the lack of communication. Subsequently, the management holds you accountable, and sorting out the problems is up to you.

In today’s fast-paced environment, you are required to respond to issues quickly and efficiently to stay competitive.

What is a Lean Daily Management System?

A Lean Daily Management System consists of tools, principles and methods. Some of which are easy to adopt and benefit from immediately, while some will require more practice.

Performance Management

Establish relevant KPIs to track performance and measure against daily targets. This will help stay focused on value adding activities.

It’s critical that the metrics are actually reflecting the result of value adding activities, that they are relevant for the team using them, and that it’s a metric that the team’s performance can influence.

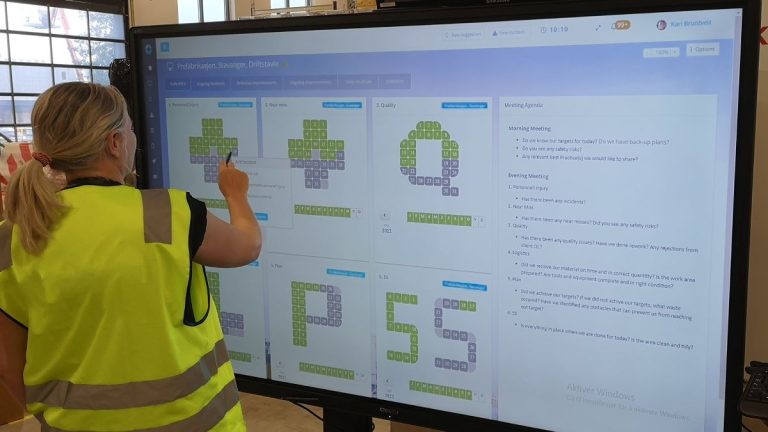

Visual Management

It’s very typical that management complains about lacking results to the surprise of the operators. They weren’t aware of their targets. Key performance indicators is an unfamiliar term only used by white collars.

Share information with your team. Add transparency by visualizing the information on daily management boards and allow the team to interact with it. With hands-on reporting, you are adding ownership and awareness and enabling quicker response to lack of performance.

Even better, a digital daily management system can provide live data instead of manually extracting data from your ERP system or Excel sheets. All you need to do is review the performance, take action and move forward.

Daily Huddles

Establish a daily meeting routine to review yesterday’s results, any learnings, handovers, today’s plan and share if there are any issues that need resolving. The daily huddle becomes a safe and predictable place for sharing and communicating.

Delegate actions and responsibilities. Define targets.

With visual management, you capture delays and problems early, enabling a quicker response and less waste.

Standardized Work

Standardized work is a method to built quality into your process. Having best practices and procedures in place will ensure a consistent work execution and improve efficiency.

This will reduce variance and time wasted on suboptimal work processes, or not using best practices.

Problem-Solving

Make your workers problem-solvers by involving them in the process. To strengthen engagement and ownership, solve problems at the lowest level possible. As an extension of the shop floor daily management, the LDMS also consist of daily meetings on the next levels (tiers). Problems that cannot be solved on the floor are quickly escalated to a higher level tier.

When you also operate these tiered meetings on a digital platform, it’s improving the collaboration, transparency and follow-up significantly compared to transferring messages on post-its or orally between meetings, all depending on the supervisors.

Challenges In Implementing Lean Daily Management

Resistance To Change

People appreciate what they have. Habits impose knowledge, and introducing fundamentally new ways of thinking is not always welcome.

Multiple factors affect the resistance to change:

- Fear of the unknown

- Loss of control

- Threat to status or security

- Lack of communication

- Breaking habits

- Culture

The big question is, “WHY?”

Successful change processes involves the people, sharing the purpose and value of the change. Involving the people adds ownership to both the process and the outcome.

Continuous Improvement

Understanding and believing in the concept of continuous improvement is sometimes hard. It may be challenging to understand what kind of improvements to suggest, and the expectations. Emphasize the iterative nature of the lean daily management and how that contributes to process improvement.

Sustaining Lean Daily Management

The lean daily management system needs to be valuable to all stakeholders, and it must reflect in the KPIs.

The system needs to be easy to maintain for daily use, and as little person-dependent as possible.

In many cases, a single person with access to the metrics updates the daily management boards, and once this person is unavailable, the boards are outdated and lose traction.

Having a transparent system to provide feedback on actions, accountability, improvements and incidents build trust.

And to top it off, if the lean daily management system can integrate with other systems avoiding double booking, you are actively reducing non-value adding time (waste).

Learn more about DigiLEAN as a Lean Daily Management System